As mentioned in an earlier post, gasification is typically done with wet biomass or dry biomass. Usually, dry biomass is thrown into a furnace under ideal conditions and goes through a thermochemical process that forces the solid substance to release a flammable gas known as syngas. With wet biomass, there is another option of sending the material through a biochemical process where enzymes and bacteria do magical things in the absence of oxygen that create a usable liquid fuel. Just as before, we are going to focus on the thermochemical process where combustion is the name of the game.

An interesting fact about the thermochemical process is that after the flammable gas is extracted from the fuel source, it too can go through additional chemical processes and become a usable liquid fuel much like diesel or ethanol. The first embedded videos talks about this process. If not made into a liquid fuel, the other option is to burn the flammable syngas in an engine to produce electricity and/or heat. Burning the syngas onsite is the typical process of facilities being built today. This process is depicted by the second video.

The truth is that the videos can probably do a much better job of explaining the process of gasification, but I am going to attempt to list the major steps and some important details along the way.

1. Procurement- Fuel such as wood chips, switch grass, agricultural plant waste, or pellets are delivered, stored and dried as much as possible.

2. Feed system- For a large power plant, the fuel is typically automatically fed into the boiler via a conveyor system with controls allowing an operate to adjust how much fuel is going into the boiler at any time. Also, exhaust heat from later processes is often funneled to the stored fuel to reduce the moisture content and therefore increase efficiency.

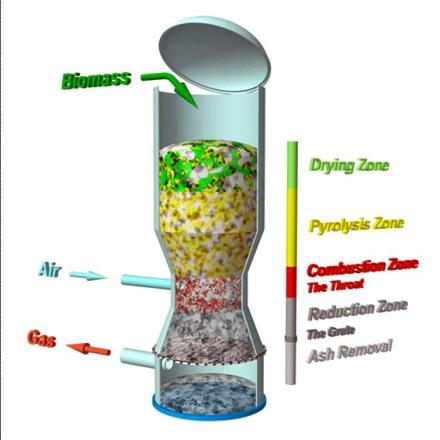

3. Gasification- When the fuel is place in the gasification chamber, it is essentially closed to outside air. This is where the heart of the process lies. There is a bed of hot charcoal already in the chamber and air is let in via small nozzles around the combustion zone. In doing this, there is enough heat causing the biomass to be broken down into smaller components, but there is not enough oxygen for all of the fuel to combust (remember that fire requires oxygen). This chemical reaction is complex but the net result is a release of hydrogen gas and carbon monoxide, both of which are highly combustible. The byproduct is charcoal or ash. The amount of hot charcoal left in the reactor to heat the incoming fuel is monitored and kept at ideal volumes.

4. Cleaning & Cooling-The combustible gas is not without contaminates. The first step is to run the gas through a cyclone that essentially uses a fan to drop out solid particles via gravity. Second, water is introduced into the system often as a mist to cool the gas and to remove additional particulates. This is often called scrubbing. Different designs will begin to vary on how they cool and clean the syngas at this point. Both videos talk about different processes utilized.

5. Filters-Although the cyclone and water treatments have removed most of the contaminants, the gas still needs further cleaning. The gas is passed through a series of filters, some of which are similar to air filters you may find in your home or car, although their design is much more sophisticated. After going through the filters, you are left with a very clean usable gas.

6. Uses-As demonstrated in the Ankur Product video, the gas is piped directly to an internal combustible engine (similar to the one in your car) which is connected to a generator that converts the mechanical energy into electrical energy. In the shorter video, the end result shows the option of producing liquid fuels such as diesel, jet fuel and alcohol. These processes are possible, but are still in the development phase.

These are the main steps in a gasification facility. I think both of the videos below do an excellent job animating the process, if you can handle the background music. Both videos bring to light different ways that the process can be achieved.